Genable 3000 Series

Graphene-Based, Non-Metal,

Active Anti-Corrosion Additives

Innovate…

…by maximising the synergies of complimentary chemical additives to benefit from a combined impact

Perform…

…with the highest protection system to extend the life of surfaces and structures in extreme environments

Stand Out…

…to gain a competitive advantage in the industry with graphene-enhanced materials that are truly unique

Anti-corrosion graphene additives for enhanced coating performance

Significant Life Cycle Benefits

Anti-corrosion coatings are designed to prevent rust by forming an effective barrier against water and detrimental ions. However, surfaces painted with traditional anti-corrosion primers and exposed to the most harsh conditions are still not seeing the level of protection required.

Using a combination of graphene with traditional, sacrificial anti-corrosion additives offers a boost in corrosion prevention, extending the life of the coating and increasing the necessary maintenance cycles to reduce costs. Anti-corrosion graphene additives enhance the coating performance.

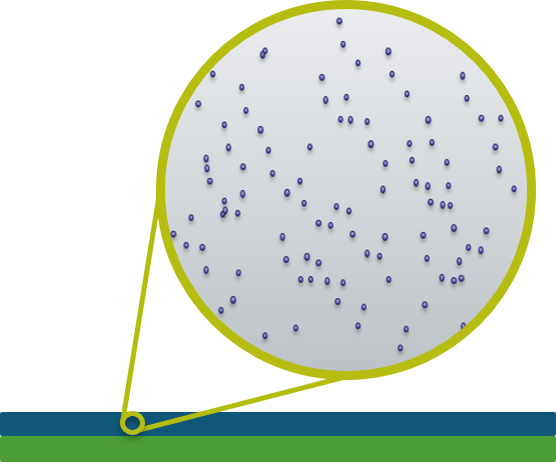

Traditional Sacrificial Anti-Corrosion Pigments

Why innovate with graphene?

Traditional sacrificial pigments, like zinc phosphate, are added to a coating formulation to shield the metal from the environment.

The reactive additive material oxidises when it comes into contact with corrosive species passed through the coating. This extends the time taken for corrosive particles to reach the metal surface. However, once all the sacrificial material is exhausted, corrosion protection is lost.

Anti-corrosion graphene additives have the potential to enhance the coating performance even further…

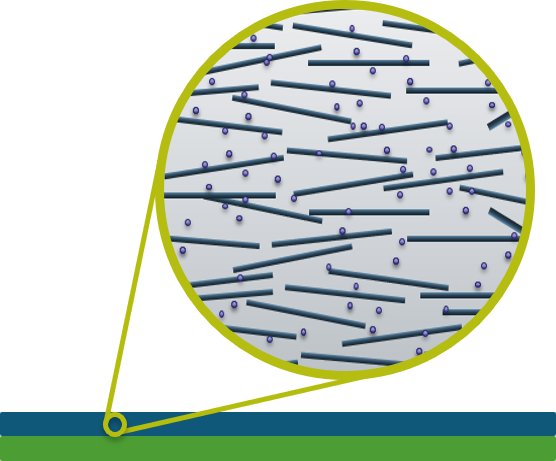

Maximum Corrosion Protection with Graphene Synergies

Anti-corrosion graphene additives for enhanced coating performance

The unique combination of high surface area graphene nanoplatelets with reactive sacrificial additives has the potential to take the anti-corrosion properties of an industrial coating to the next level.

AGM’s Genable 3000 series of optimised, active, metal-free hybrid graphene dispersions offer the paints and coatings industry an innovative solution that will boost the performance of their anti-corrosion materials even in the harshest of corrosion environments.

Introducing Genable 3000 Graphene Dispersions…

Hybrid graphene dispersions that are stable, easy to formulate and safe to incorporate

For industry-leading protection against corrosion, your high performance coating could incorporate one of three graphene-based dispersions from AGM’s Genable 3000 series.

Genable 3100 and Genable 3105 are formulation ready dispersions stabilised in a standard epoxy resin, while Genable 3120 offers a more sustainable option in an eco-friendly, biobased epoxy resin.

Why not explore anti-corrosion graphene additives for enhanced coating performance?

Sustainable Coatings

Materials suppliers are being driven to innovate with environmentally friendly alternatives, from reducing VOC emissions to biobased materials as customers become increasingly aware of the environmental impact of the raw materials they use.

Growing pressure to comply with increasingly stringent regulatory legislation and demonstrate a reduced carbon footprint is forcing manufacturers to progressively introduce VOC free and bioderived alternatives to traditional chemicals.

AGM’s Genable 3000 series of metal-free and VOC-free hybrid graphene dispersions offer the paints and coatings industry an innovative solution that will boost the performance of their anti-corrosion materials, whilst contributing to sustainability goals.