Industrial Paints and Coatings

Speciality graphene additives can be incorporated into high performance epoxy or polyurethane industrial paint and coating systems through the use of UM’s Genable dispersions.

Protective coatings often utilise additive materials that are optimised for surface protection applications to improve their physical and mechanical properties, such as corrosion and chemical resistance, as well as anti-static and conductivity.

Graphene’s two-dimensional structure in the nanoplatelet form results in high aspect ratio, high surface area advanced materials which are particularly suited for use as multi-functional additives in industrial paints and coatings.

How do UMs Graphene Nanoplatelets work?

AGM is proud to offer graphene nanoplatelet dispersions that are safe to handle and easily stirred into new and existing coatings systems to provide a range of performance-enhancing benefits. Across our product ranges, we offer different types graphene nanoplatelets. These vary in surface morphology, oxygen content and the number atomic layers, but they typically have a thickness between 1 to 10nm with 1-25µm lateral platelet diameter. This gives aspect ratios up to 1:1000 and surface areas up to 700m2/g.

With the correct incorporation, graphene nanoplatelets have the potential to significantly enhance an array of properties, including mechanical, barrier, thermal, lubricating and electrical performance in new and existing industrial systems.

Performance Additives for Better Industrial Coatings

By incorporating a standard or customised Genable dispersion, UM is enabling coatings formulators to easily innovate and realise the true benefits of graphene.

Adding a graphene dispersion as a complimentary anti-corrosion additive can extend the life of industrial coatings and the assets.

Excellent results are possible, either as a stand alone corrosion inhibitor, or as a result of the synergistic performance of the graphene in combination with existing systems.

Incorporating graphene into a high performance coating can increase its resistance to harsh chemicals and offer greater surface protection.

The chemical resistance benefits of graphene are clear from our comprehensive data package, showing less blistering, an improvement in gloss retention and greater shore hardness.

Electrically conductive coatings can effectively disperse electrical charges, helping to stop the buildup of anti-static electricity on the surface.

As a functional nanomaterial, graphene nanoplatelets transmit electrical current through a paint, allowing it to create a preferred pathway for the electricity flow.

UM’s graphene nanoplatelets have a two-dimensional form that can also be employed to develop thermally conductive materials.

Thermal management materials enhanced with graphene help to dissipate heat build-up from components and facilitate rapid heat transfer.

Why Choose Graphene as a Functional Ingredient?

As a flexible and innovative solution, graphene enables the development of better performing industrial paints and coatings that are also kinder to the environment.

Graphene offers product life cycle advantages and reduces the environmental impact of paints and coatings, as an eco-friendly, metal-free alternative to traditional additives:

- Extended asset service life and reduced maintenance.

- Potential reduction of toxins like zinc, chromates etc.

- Fewer, thinner coats required due to improved performance.

- Graphene dispersions are available in a selection of waterbased, biobased and low VOC carrier media.

Working with UM to Incorporate Graphene Technology

UM has developed an industry-leading position in the graphene industry.

A recent survey from The Graphene Council showed the dispersibility of graphene nanoplatelets is essential to achieving success in an application. UM expertise lies in the consistent supply of high quality, repeatable graphene dispersions that are stable, easy to formulate and safe to incorporate into a range of applications, supported with in-depth test data.

Offering a decade of experience, the latest lab technology and the stringent environmental controls required to handle graphene powder, UM’s expert team of chemists can work with you to incorporate graphene additives so you can offer customers next generation industrial coatings.

What Our Customers Say

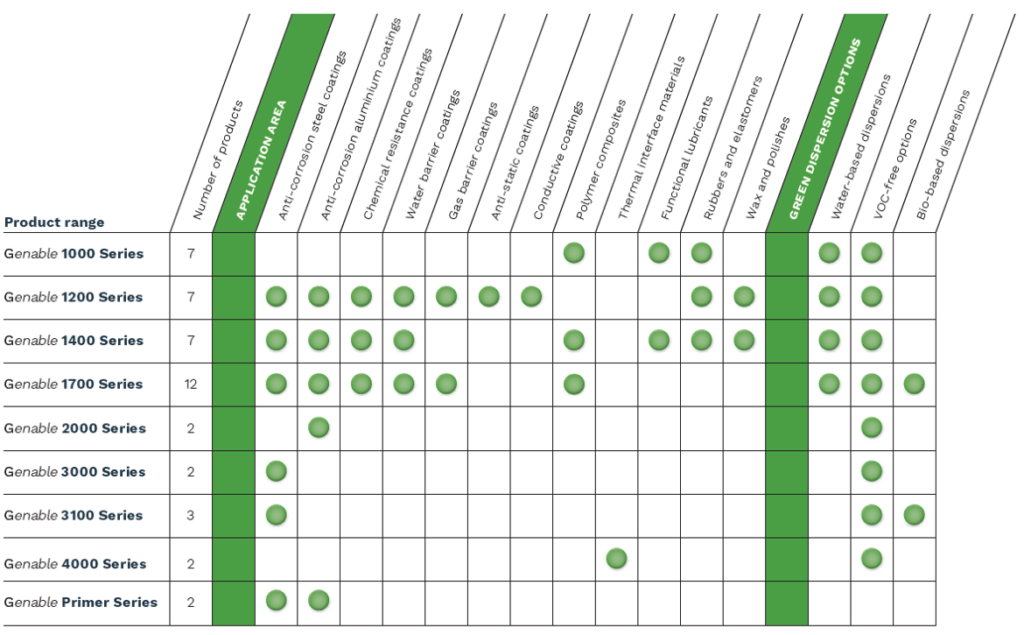

Graphene Dispersion Range Overview

If you what to learn more about how our graphene nanoplatelets work, and the range of performance benefits that can be achieved, visit our Knowledge Hub.

For more information about our customer success stories visit our Customer Case Studies.

As a growing global manufacturer of graphene dispersions for the paints and coatings sector, UM is a proud member of the British Coatings Federation and the American Coatings Association.

To speak to a member of our sales team and find out how you can get ahead of the competition using graphene nanoplatelets. Call us on +44 (0)1642 438214 or drop us a message via our Contact Us page.